Getting Creative with the Grain

I have mentioned on several occasions how much I love working with wood. As I became familiar with the tools I was being introduced to, I was more eager to work a new skill into my hobby. It took about three different projects under my belt before I felt ready to tackle the scroll saw.

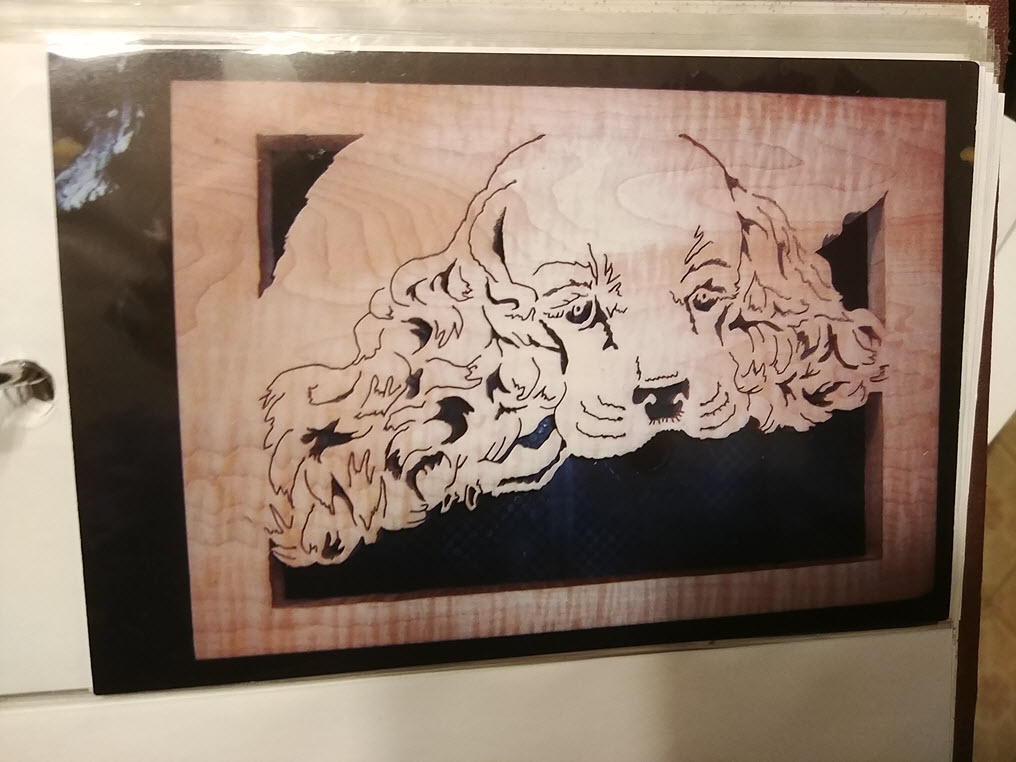

I saw this pattern of a Cocker Spaniel and decided to give it a try. When I purchased the design and read the instructions, I was relieved to know that they mentioned the type of wood used to create the project. Being as new to woodworking as I was, I still needed help identifying wood grains.

The wood used is in this picture is called Curly Maple. The name itself shows how appropriate this wood was for the subject being scrolled into it. I had chosen to use a spiral blade instead of the regular flat blade. I discovered that turning the wood piece as it moves against the saw blade needs to be done quickly. With a spiral blade, you can move the work forward, backward, or sideways, and the blade is still cutting the wood. I am not sure why I never tried to use the flat blade and just stopped the scroll saw each time I had to turn the wood. I suppose I was being impatient to begin this piece.

After tracing the picture onto the wood, the first hurdle to this project was to drill out tiny holes in the areas that would be removed.

In my gallery, I have a few pictures that show some of the accessories I have used to aid in the sawing and finishing of the completed project. These were all acquired after this project. The only tool to drill holes at this time was a drill press that was bolted to one of my benches. I have put a few pictures in here to show how small the drill bits are and the difference between a flat saw blade and a spiral blade.

The spaniel picture took me a few days to cut, but I was successful in cutting every line and curl in its fur. Giving myself a quick pat on the back, I moved on to my next hurdle. It was to sand out any of the rough spots caused by the blade. When planning this intricate project, I didn’t consider how working with such thick wood (3/4in) with such fine lines could be so stressful getting the sandpaper between those lines.

By the time this project was ready for its forever home, I had learned a great deal about the process from start to finish on a scroll-sawed gift.

. . .